Description

Self feed drilling unit is a air-feed and electric rotation, body-mounting drilling unit that lines up electric motor type with output of 1.5 kW and 2.2 kW, features pneumatic feed drilling with rapid advance, cutting feed speed is freely controlled by hydro speed regulator, It is capable of heavy-duty cutting.

Model: PR6P

No-load speed: 220-3500R/M

Drilling diameter: Aluminum: 9-24mm / Cast iron: 3-21mm / Steel: 3-19mm

Spindle stroke: 150mm

Cutting feed stroke: 40mm, 60mm, 80mm,100mm,130mm

Motor power: 1.5/2.2kw

Feed thrust: 5200N

Air consumption: 14L

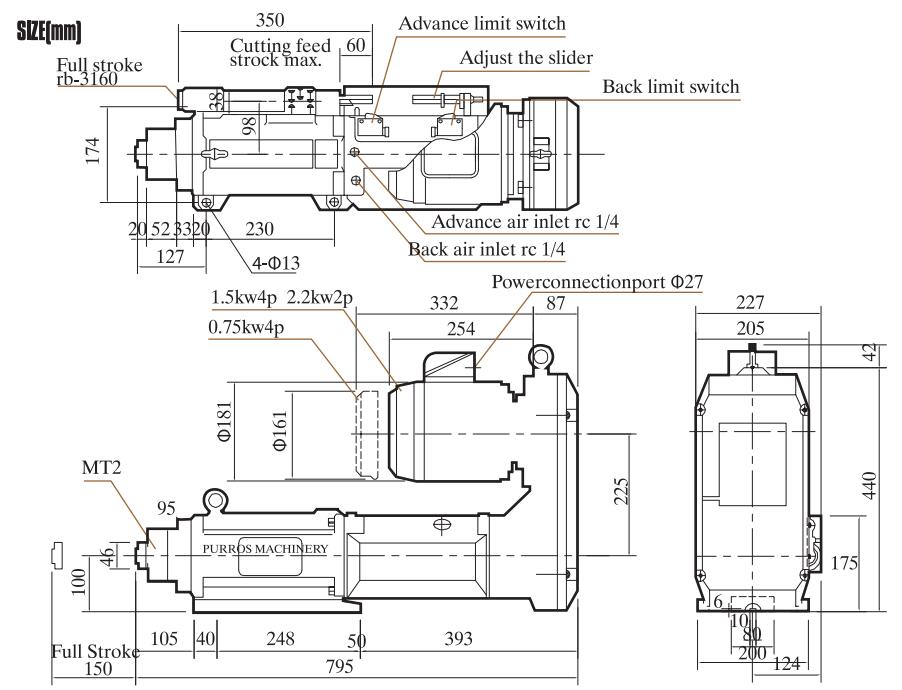

PURROS® Self Feed Drilling Unit PR6P Size

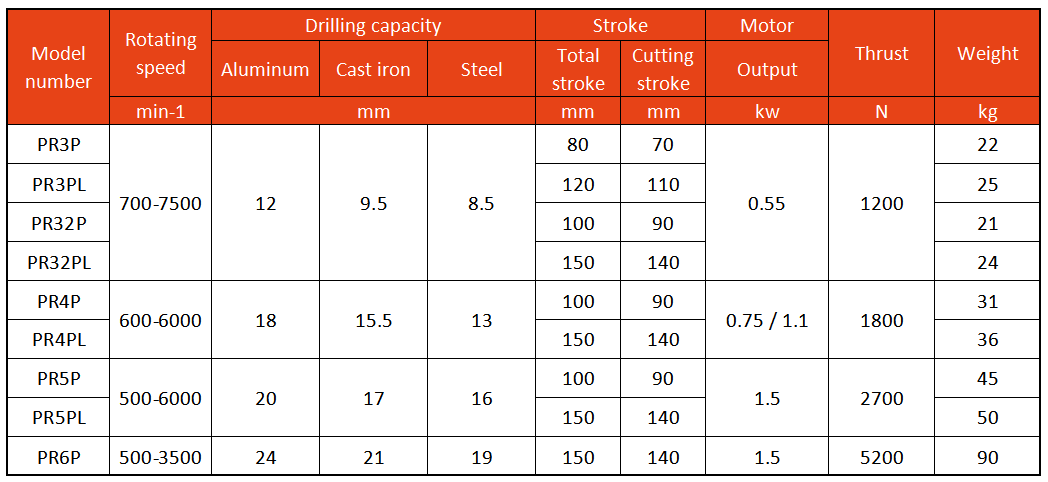

PURROS® Self Feed Drilling Unit PR6P Parameter

| Model number |

No-Load rotational speed | Chucking capacity |

Drilling capacity | Stroke | Motor | Thrust | Weight | |||||

| 50 Hz | 60 Hz | Aluminum | Cast iron | Steel | Total stroke |

Cutting stroke |

Output | Poles number |

||||

| min-1 | mm | mm | mm | mm | kw | P | N | kg | ||||

| PR6P-2435 | 3500 | 4200 | MT2 | 9 | 3 | 3 | 150 | 0-100 | 2.2 | 2 | 5200 | 100 |

| PR6P-2422 | 2200 | 2700 | 12 | 4 | 4 | |||||||

| PR6P-2414 | 1400 | 1700 | 14 | 6.5 | 6 | |||||||

| PR6P-2411 | 1100 | 1300 | 16 | 9 | 8 | |||||||

| PR6P-2408 | 850 | 1000 | 18 | 11 | 10.5 | |||||||

| PR6P-2407 | 700 | 850 | 19 | 14 | 12.5 | 1.5 | 4 | |||||

| PR6P-2406 | 550 | 650 | 20 | 16 | 15 | |||||||

| PR6P-2405 | 500 | 600 | 21 | 17 | 16 | |||||||

| PR6P-2404 | 400 | 480 | 22 | 18 | 17 | |||||||

| PR6P-2403 | 350 | 430 | 23 | 19 | 18 | |||||||

| PR6P-2402 | 220 | 270 | 24 | 21 | 19 | |||||||

NOTE:

1. The selection of models should be based on the shape of the work, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

2. The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

3. The standard attachment for the hydro speed regulator is RB-3140. Please specify an optional Hydro Speed Regulator if required. (Optional Hydro Speed Regulator Models: RB-3160, RB-31100, R-3180A, R-31130A)

4. Maximum weight of the attachment that can be mounted when machining downwards is 50 kg.

5. Make sure to use a collet chuck or spindle nose when the hardness of carbide drills and tool shanks is higher than that of general HSS (high-speed steel) drills.

PURROS® All Self Feed Drilling Unit Parameter

Click in: PR3P PR32P PR4P PR5P

Features:

1. High-precision

Core technology of Electro Pneumatic Drilling Units is played very well, which completely strengthened the versatility of the product and thus made the high precision of Drilling Units reflected extremely.

2. High rigidity

Axial rail structure is used, which greatly improved the overall rigidity and fully guaranteed the stability of the hole machining.

3. High performance

A unique dual sealing structure and round body that is easy and convenient to be installed are available at the end of spindle, which can meet variety of holes machining requirement.

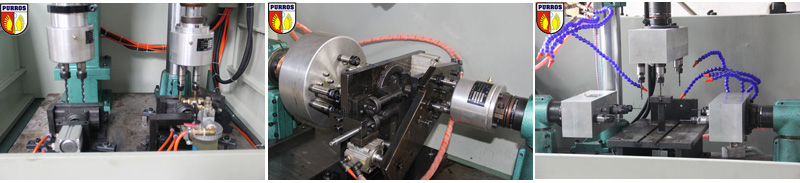

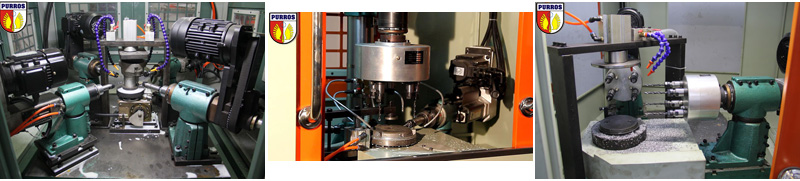

Products can be equipped with Self Feed Drilling Units

1. PURROS® Hydro Speed Regulators

Speed can be adjusted arbitrarily from lower to higher by a hydraulic feeding speed control device.

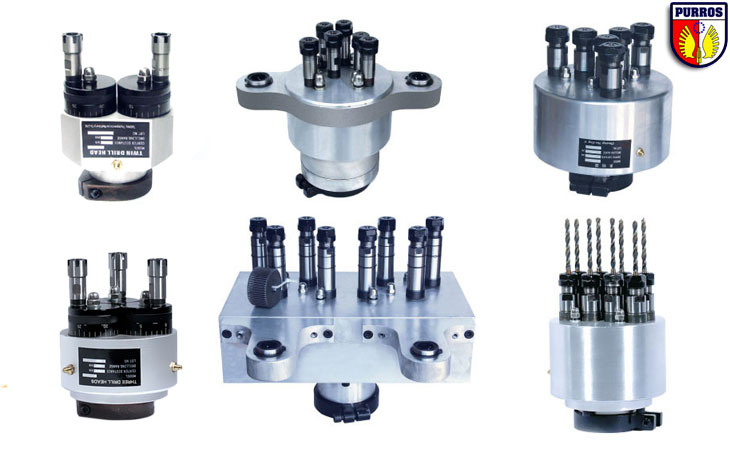

2. PURROS® Multiple Spindle Heads

Multiple Spindle Heads can be amounted, which can achieve high efficiency drilling and meet different requirements of machining spindle and spindle spacing. Extensive Multiple Spindle Heads sizes are available in PURROS®.

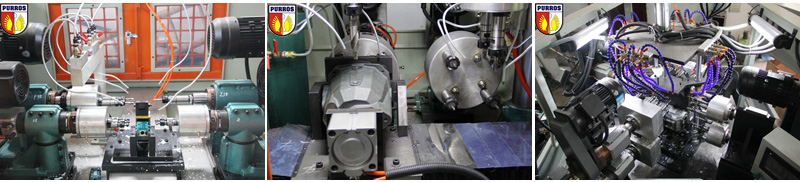

PURROS® Special Purpose Machines

Multiple Drilling or Tapping Machine

Multi Station Drilling or Tapping Machine

Rotary Index Drives Special Purpose Machine

Sliding Table Special Purpose Machine

Rotary Table Special Purpose Machine

Reviews

There are no reviews yet.